Engraving is the process of incising a design or text onto a hard surface, often to create prints or decorations on various materials such as metal, wood, glass, and paper.

This technique has been used since ancient times and has evolved significantly over the centuries with advancements in technology.

Let’s take a closer look at the evolution of engraving machines and how they have transformed over time.

Hand Engraving Tools

In the beginning, people used basic hand tools for engraving. They used chisels, hammers, and other sharp instruments to carve intricate designs into various materials like:

- wood

- stone

- metal

This was a slow and labor-intensive process that required a lot of skill and dedication. Skilled artisans would spend hours, sometimes even days, working on a single piece to ensure every detail was perfect. Hand engraving requires patience and precision because even a small mistake could ruin the entire design.

Mechanical Engraving Machines

The next big step in engraving came with mechanical machines. These devices used motors and gears to help carve designs more quickly and accurately. One popular machine was the pantograph. Invented in the 17th century, the pantograph allowed engravers to trace an original design onto a new surface.

This made it easier to produce multiple copies of the same design. Mechanical engraving machines improved efficiency and precision.

CNC Engraving Machines

CNC (Computer Numerical Control) engraving machines represented a significant technological advancement. These machines rely on computers to manage the engraving process. By inputting a design into the computer, the machine can replicate it with remarkable precision and detail.

CNC machines are faster. It’s also more dependable than older mechanical models. They are versatile, capable of working with various materials, and can produce intricate designs that would be difficult to achieve by hand. This leap in technology has revolutionized the way engraving is done, making it more efficient and accurate.

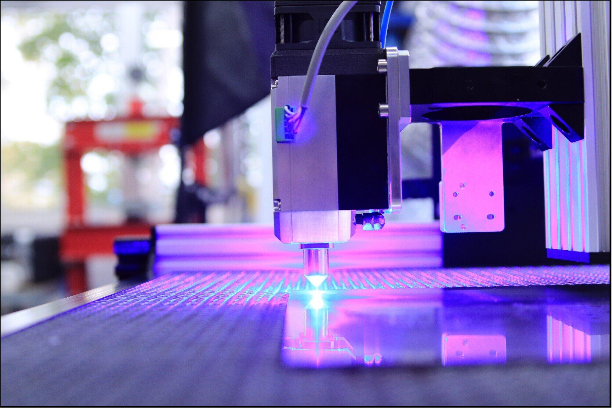

Modern Laser Engraving Machines

The latest innovation in engraving technology is the laser engraving machine. These devices use high-powered lasers to cut or etch designs onto various materials. A laser cutter can produce very precise, intricate designs at a much faster rate than traditional methods.

They are also versatile and can work with a wide range of materials, from wood and metal to plastic and even glass. Because of this versatility, laser cutters are commonly used for:

- creating signage

- personalized gifts

- industrial applications

3D Printing and Engraving

The newest addition to the world of engraving technology is 3D printing. This innovative technique uses a digital model to create three-dimensional objects by adding layer upon layer of material. By combining 3D printing with engraving, designers and engineers can create intricate and complex designs in a wide range of materials. This includes:

- metal

- plastic

- wood

This cutting-edge technology has opened up new possibilities for creating unique and personalized products. Products that were previously impossible to achieve with traditional methods.

Know More About the Evolution of Engraving Machines

Engraving machines have come a long way from simple hand tools to modern laser cutters and 3D printers. These advancements have made the engraving process faster, more precise, and accessible to a wider range of industries and applications.

As technology continues to evolve, we can expect to see even more innovative and exciting developments in the world of engraving machines. Remember, the long journey that engraving has taken from its humble beginnings to its current state of modern technology!

Did you find this article helpful? Check out the rest of our blogs!

Stay in touch to get more updates & news on Tribunebreaking!