The “Extruded Wood Pencil Eagle” marks a significant development in the history of pencil manufacturing. Known for their exceptional lead quality and unique craftsmanship, Eagle pencils have been at the forefront of the industry for decades. Over time, advancements in technology led to the integration of new materials and techniques. The introduction of extruded wood and composite materials revolutionized pencil production, transitioning from traditional wooden casings to more durable, eco-conscious alternatives. This article explores the origins, manufacturing processes, and impact of the “Extruded Wood Pencil Eagle” on the evolution of modern pencils.

What Is An Extruded Wood Pencil Eagle?

An extruded wood pencil is crafted using a modern manufacturing process in which a blend of wood pulp and resin is molded and extruded into shape, unlike traditional pencils made from solid wooden slats. This innovative technique emerged as an efficient solution for mass production, significantly reducing wood waste while promoting environmental sustainability. The process not only minimizes the need for harvesting large amounts of timber but also repurposes wood byproducts, aligning with the growing demand for eco-conscious products.

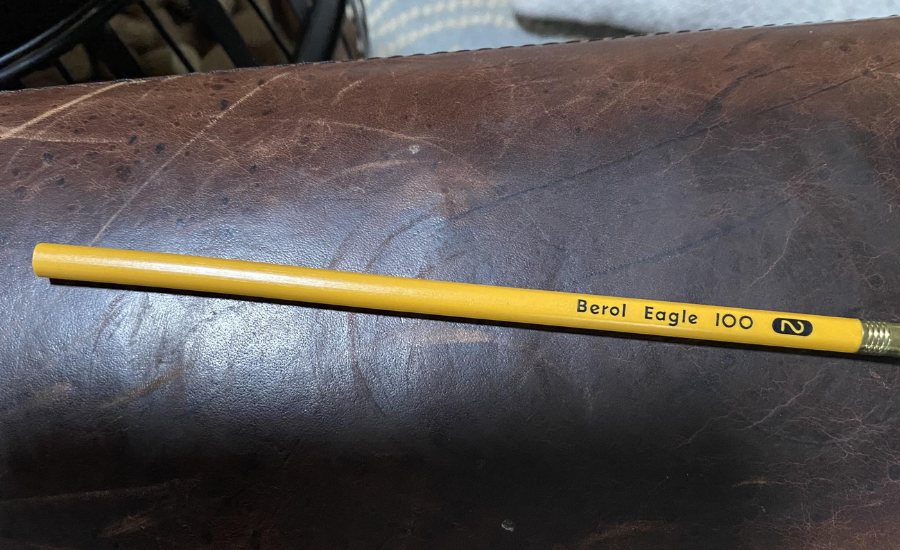

One of the early adopters of this approach was the Eagle Pencil Company, which was founded in the late 1800s and quickly gained a reputation for its commitment to quality and innovation. Eagle’s use of extruded wood in some of its pencils represented a shift in the industry, offering consumers a product that was not only durable but also provided a smooth, high-performance writing experience.

The term “Extruded Wood Pencil Eagle” refers specifically to the pencils produced by the Eagle brand utilizing this manufacturing method. These pencils became widely recognized for their durability, excellent lead consistency, and ability to withstand frequent use. Artists, writers, and professionals appreciated the reliable quality of these pencils, which combined the traditional feel of a well-crafted pencil with the practical benefits of modern materials.

Eagle’s innovation through extruded wood manufacturing not only contributed to their brand legacy but also influenced broader industry trends, encouraging the adoption of sustainable materials without compromising product performance. As a result, the “Extruded Wood Pencil Eagle” stands as a symbol of ingenuity and environmental responsibility, offering a glimpse into how thoughtful manufacturing can blend tradition with modern needs.

The History Of Eagle Pencils And Extruded Wood Technology

Founded in New York in 1856, the Eagle Pencil Company built its reputation on producing high-quality wooden pencils. Known for their craftsmanship, these early pencils were made from solid cedar wood, which was valued for its durability, smooth sharpening, and long-lasting use. For many years, Eagle’s products reflected the gold standard of traditional pencil-making, combining premium materials with attention to detail.

However, as awareness of environmental issues grew and the demand for more sustainable manufacturing practices increased, the pencil industry began searching for alternatives that could reduce the use of natural wood. This shift in priorities led to the development of extruded wood technology—an innovative approach that allowed manufacturers to use fewer resources while maintaining product quality.

The transition to extruded wood marked a pivotal moment for Eagle pencils, especially during the mid-20th century, when the company’s operations were absorbed by larger industry players such as Berol and Sanford. This new manufacturing technique offered greater efficiency, as wood pulp blended with resin could be molded into pencil shapes without the need for labor-intensive woodcutting or assembly.

Beyond streamlining production, the extrusion process brought other advantages. It ensured consistency in pencil quality by allowing the lead core to be embedded smoothly within the body, reducing the risk of breakage or misalignment. This method also enhanced flexibility, enabling manufacturers to produce pencils in various designs and styles without being limited by the dimensions of wooden slats.

The introduction of extruded wood technology not only allowed the Eagle brand to adapt to changing market demands but also positioned it as a pioneer in sustainable manufacturing practices. This innovative approach paved the way for a new era in pencil production, blending environmental responsibility with the durability and performance that users had come to expect from Eagle pencils.

How Extruded Wood Pencil Eagle Is Manufactured

Extruded wood pencils are created through an advanced manufacturing technique known as co-extrusion, where wood pulp is combined with resin to form a continuous pencil casing. This process not only eliminates the need for solid wooden slats but also supports sustainable practices by utilizing recycled materials or wood sourced from responsibly managed forests. As environmental consciousness grew, this method aligned perfectly with the eco-friendly direction embraced by the Eagle brand over time.

The production begins by preparing a mixture of wood pulp and resin, which is then fed into an extrusion machine. The material is shaped into long cylindrical forms through this process, producing an unbroken length of pencil casing. Unlike traditional manufacturing methods, where lead is inserted after the pencil body is made, the co-extrusion process allows the graphite core to be embedded directly into the casing during extrusion. This ensures that the lead remains perfectly centered and securely supported, reducing the risk of breakage during use.

Once the continuous pencil length is extruded, it is cut into individual pieces, forming standard pencil sizes. To enhance both durability and aesthetics, each pencil undergoes a finishing process where it is coated with layers of paint and lacquer. These coatings not only protect the surface from wear and tear but also provide a smooth, polished finish for a comfortable writing experience.

The co-extrusion technique revolutionized pencil manufacturing by offering a more sustainable alternative to traditional wooden pencils. By reducing the reliance on solid wood and promoting the use of recycled or renewable materials, the “Extruded Wood Pencil Eagle” became a model of environmentally conscious production. This innovation demonstrated how modern manufacturing could balance high-quality craftsmanship with ecological responsibility, making it an ideal choice for consumers seeking both performance and sustainability.

Why Extruded Wood Pencil Eagle Stands Out

The “Extruded Wood Pencil Eagle” series distinguishes itself in several ways, making it a preferred choice for a wide range of users.

1. Superior Durability:

The extruded wood manufacturing process produces pencils that are significantly more resistant to cracking and breakage compared to traditional wood-cased models. The combination of wood pulp and resin creates a tough, flexible casing that can withstand drops, pressure, and frequent sharpening. This enhanced durability makes these pencils ideal for students, professionals, and artists who require dependable tools for everyday use. Whether sketching, writing, or drafting, users benefit from a pencil that performs reliably over time.

2. Environmentally Friendly Materials:

A core feature of these pencils is their eco-conscious design. By replacing solid wood with a composite of wood pulp and resin, the manufacturing process reduces the need for cutting down trees. The use of recycled or sustainably sourced wood pulp further minimizes the environmental impact. Eagle’s commitment to sustainable practices has made these pencils particularly appealing to eco-conscious consumers who seek products aligned with environmental responsibility.

3. Consistent Performance and Quality:

A major advantage of the extrusion process is the precision it brings to pencil production. In traditional wooden pencils, lead cores can occasionally be misaligned, causing uneven writing or lead breakage. However, extruded wood pencils eliminate these inconsistencies by embedding the graphite core seamlessly within the casing during the extrusion process. This ensures a smooth, uninterrupted writing experience, with consistent quality from one pencil to the next.

The Legacy Of The Eagle Pencil Brand

The Eagle Pencil Company played a pivotal role in shaping the evolution of the modern pencil industry. Although the brand eventually merged with larger companies like Berol and Sanford, the impact of Eagle’s innovations in pencil-making continues to resonate. One of the most transformative developments introduced by Eagle was the adoption of extruded wood technology, which marked a new chapter in pencil manufacturing. This shift allowed for the creation of high-quality writing instruments with a reduced environmental footprint, setting new industry standards.

Even today, collectors actively seek out vintage Eagle pencils, especially those produced before the company’s merger with Berol and Sanford. These early models—whether crafted from solid wood or using extruded materials—are cherished for their exceptional craftsmanship. Known for their superior lead quality and smooth writing performance, these vintage pencils have become valuable items for enthusiasts and collectors alike.

The transition from traditional wooden casings to extruded materials reflects Eagle’s adaptability in response to changing market demands and environmental concerns. The brand’s ability to embrace innovative production techniques not only extended the life of its legacy but also demonstrated how companies could evolve to meet new challenges without compromising quality. Eagle’s forward-thinking approach set a precedent for sustainable practices in the pencil industry, ensuring that its influence remains evident even in modern pencil designs.

Environmental Impact Of Extruded Wood Pencil Eagle

One of the primary drivers behind the shift to extruded wood pencils was the growing focus on sustainability. By utilizing wood pulp—a byproduct of the paper production process—the Eagle brand and its successors played a role in reducing the need for virgin timber, helping to mitigate deforestation. This approach allowed manufacturers to make efficient use of materials that might otherwise be discarded, aligning with the principles of sustainable production. The inclusion of resin in the mixture further enhanced the durability of these pencils, giving them a longer lifespan compared to traditional wood-cased pencils.

The environmental benefits of extruded wood pencils extend well beyond the manufacturing process. Their increased durability means that they are less prone to breaking, reducing the frequency of replacements and sharpening. As a result, users generate less waste over time. Additionally, the materials used in extruded pencils contribute to their structural integrity, making them resistant to cracking or splintering, even with heavy use.

As awareness around environmental issues continues to rise, the “Extruded Wood Pencil Eagle” stands as a shining example of how companies can innovate without compromising ecological responsibility. This transition from conventional wooden casings to extruded materials demonstrates how businesses can minimize their environmental impact while still delivering high-quality products. The Eagle brand’s embrace of this technology not only extended the life and usability of its pencils but also set a standard for sustainable innovation in the writing instrument industry.

The Future Of Extruded Wood Pencil Eagle

The future of extruded wood pencils appears promising, especially as consumers grow increasingly mindful of the environmental impact of the products they use daily. The “Extruded Wood Pencil Eagle” serves as a prime example of how traditional industries can adapt to meet the evolving demands of modern markets. By embracing sustainable practices and innovative production methods, the pencil industry has demonstrated that even time-honored tools can align with contemporary environmental values.

As advancements in materials science and manufacturing processes continue, extruded wood pencils are poised to become even more efficient, eco-friendly, and durable. Future innovations may include the use of biodegradable resins, enhanced recycled materials, or further improvements in durability, reducing the need for frequent replacements. Additionally, manufacturers might explore energy-efficient production techniques, making the entire process more sustainable.

With these ongoing developments, extruded wood pencils are well-positioned to replace conventional wood-cased pencils on a larger scale, offering consumers high-performance writing tools with minimal ecological impact. As environmental awareness continues to influence purchasing decisions, the demand for sustainable alternatives will likely grow, cementing the role of extruded pencils as a forward-thinking solution for students, professionals, and artists alike. The legacy of the “Extruded Wood Pencil Eagle” exemplifies how traditional craftsmanship can evolve to meet the challenges of a greener future, ensuring that high-quality, sustainable pencils remain a vital part of our everyday lives.

FAQs About Extruded Wood Pencils

- What is an extruded wood pencil?

It’s a pencil made by combining wood pulp with resin, shaped through an extrusion process instead of using solid wood. This method boosts durability and minimizes wood waste, making it eco-friendly.

- How does it differ from traditional wood pencils?

Traditional pencils are carved from solid wood, while extruded pencils are molded from a wood pulp-resin mix, ensuring consistent quality and less waste.

- What are the benefits of extruded wood pencils?

They are more durable, eco-friendly, and less prone to breaking. They also require less sharpening and use sustainable materials, making them a greener option.

- How did the Eagle Pencil Company influence this innovation?

Eagle pioneered the use of extruded wood technology, leading to more efficient production, reduced environmental impact, and setting a quality benchmark in the industry.

- Are extruded wood pencils more expensive?

Prices vary, but their durability makes them cost-effective over time, as they require fewer replacements and less frequent sharpening.

- What is their environmental impact?

Extruded wood pencils reduce the need for cutting solid wood and make use of recycled wood pulp. Their longer lifespan further lowers waste and promotes sustainability.

- Where can I buy extruded wood pencils?

They are available in art stores, stationery shops, and online platforms. Brands like Eagle continue to offer them for both casual users and professionals.

Conclusion

The “Extruded Wood Pencil Eagle” marks a notable advancement in the pencil manufacturing industry, blending traditional craftsmanship with modern innovation. By embracing extruded wood technology, Eagle pencils have improved both durability and writing performance while also demonstrating a strong commitment to sustainability. As environmental issues increasingly influence consumer choices, the legacy of the Eagle Pencil Company serves as a testament to how established industries can adapt and thrive in an eco-conscious landscape.

The transition from solid wood to extruded materials highlights the potential for innovative practices that cater to contemporary needs while minimizing environmental impact. Looking ahead, the growing popularity of extruded wood pencils is expected to inspire further improvements in manufacturing methods, ensuring that this distinctive writing tool continues to appeal to artists, students, and professionals alike.

Get the latest alerts and updates directly: Tribune Breaking!